The problem

A couple of months ago I started noticing my bike was making a lot of rattling sounds when I cycled over bumps. I traced the source of the sound to my fender and realized that one of the brackets holding the fender to the bike was broken.

Originally, I thought of just using epoxy to try gluing the two pieces back together (possibly reinforced with some little pieces), but Lee suggested remaking the whole bracket which was a much more elegant solution.

Creating a new bracket

I learned that there are aluminium alloys that can bend (e.g. 3003, 5052), and there are aluminium alloys that can’t (e.g. 6160). For this application we need to use ones that can bend.

After tracing out the pattern onto the piece of stock, we drilled the holes while it was still a big piece.

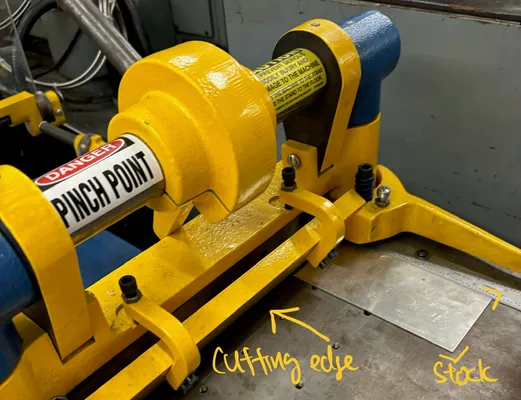

Next, we used the sheet metal shear to cut out the piece and then the belt sander to round off the corners.

We used the sheet metal brake to create the 90 degree bend.

And finally riveted the bracket to the fender, then reinstalled the fender.

Conclusion

Extremely satisfied with this fix. It was definitely the “right” way to do it and should last for a long time. It completely eliminated the jingling comming from the back of the bike when going over bumps.

Making sheet metal parts is fun! It feels super quick and easy, the tools aren’t too scary, and I think you could make some pretty large complex parts.

Update

Edit (March 2025): The aluminum bracket I made broke after 10 months. I remade it using 26 gauge zinc plated steel sheet metal this time, and it seems to be holding up much better.